產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

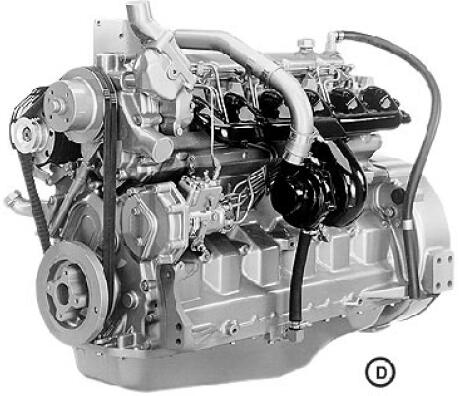

約翰迪爾強(qiáng)鹿柴油機(jī)冷卻、進(jìn)氣、排氣系統(tǒng)的檢測(cè)

詳細(xì)描述

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)冷卻、進(jìn)氣、排氣系統(tǒng)的檢測(cè)

1. Remove trash that has accumulated on or near

radiator.

2. Visually inspect entire cooling system and all

components for leaks or damage. Repair or replace as

necessary.

3. Inspect radiator hoses for signs of leakage or rot.

Replace hoses as necessary.

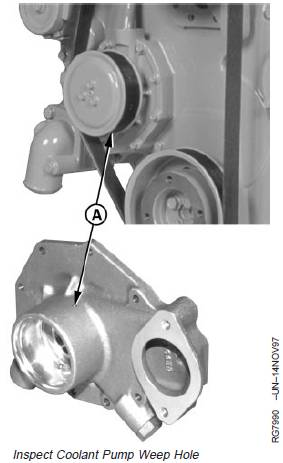

4. Inspect the coolant pump weep hole (A) for any

restrictions.

5. Insert a heavy gauge wire deep into weep hole to

make sure hole is open.

A—Weep Holes

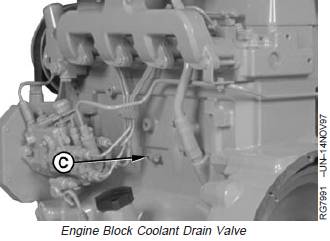

CAUTION: Do not drain coolant until it has

cooled below operating temperature. Always

loosen block drain valve slowly to relieve any

excess pressure.

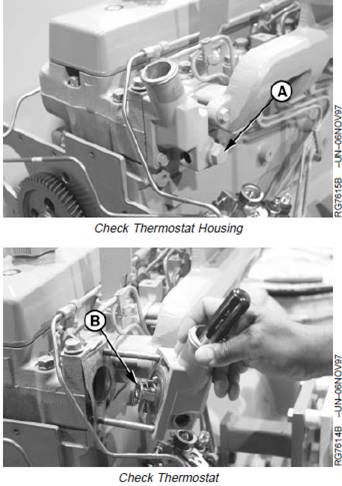

6. Remove and check thermostat(s) (B). (See TEST

THERMOSTATS in Section 02, Group 070.)

IMPORTANT: Whenever the aluminum timing gear

cover or coolant pump are replaced, the

radiator should be completely drained

by opening the radiator petcock and

removing the lower radiator hose.

Engines are now serviced with a

coolant pump insert to decrease

cavitation. When removing the coolant

pump, inspect the coolant pump cavity

in the timing gear cover for excessive

cavitation. If engine has no coolant

pump insert, install coolant pump

insert. (See INSTALL COOLANT PUMP

in Group 070.)

7. Drain coolant at drain valve (C) and flush cooling

system. (See FLUSH AND SERVICE COOLING

SYSTEM in Section 01, Group 002.)

IMPORTANT: Air must be expelled from cooling

system when system is refilled. Loosen

temperature sending unit fitting at rear

of cylinder head or plug in thermostat

housing (A) to allow air to escape when

filling system. Retighten fitting or plug

when all the air has been expelled.

8. Fill cooling system with recommended concentration of

coolant, clean soft water, and inhibitors. (See DIESEL

ENGINE COOLANT in Section 01, Group 002.)

9. Run engine until it reaches operating temperature.

Check entire cooling system for leaks.

A—Thermostat Housing

B—Thermostat

C—Drain Valve

10. After engine cools, check coolant level.

NOTE: Coolant level should be even with bottom of

radiator filler neck.

11. Check system for holding pressure. (See PRESSURE

TEST COOLING SYSTEM AND RADIATOR CAP in

this group.)

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)進(jìn)氣系統(tǒng)的檢查

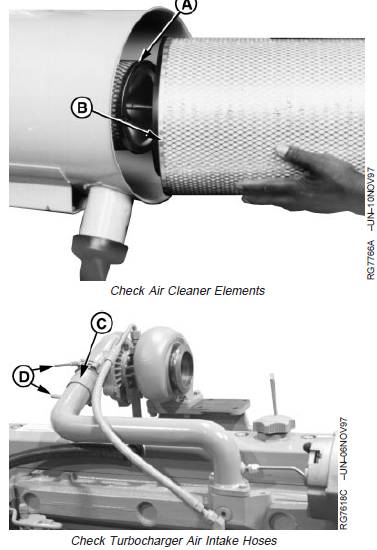

1. Replace air cleaner primary filter element (B). Replace

secondary element (A) if primary element has holes in

it.

2. Check condition of air intake hose(s) (C). Replace

hoses that are cracked, split, or otherwise in poor

condition.

3. Check hose clamps (D) for tightness. Replace clamps

that cannot be properly tightened. This will help

prevent dust from entering the air intake system which

could cause serious engine damage.

A—Secondary Filter Element

B—Primary Filter Element

C—Air Intake Hose(s)

D—Hose Clamps

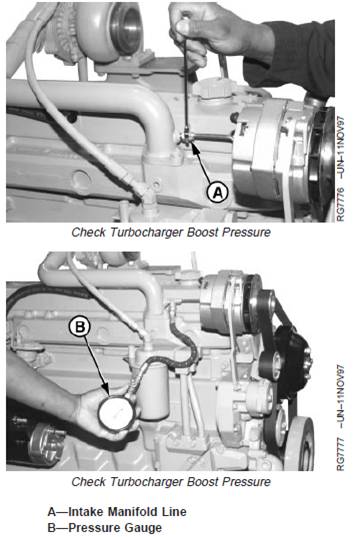

Measure Intake Manifold Pressure

(Turbocharger Boost/Power Check)

This test of turbocharger boost is also a good indicator of

whether the engine is performing at full rated power.

IMPORTANT: If testing the engine with the air filter

system removed, install JDG576

Turbocharger Shield to inlet of

turbocharger.

NOTE: On “H” engines, pressure reading should be taken

at intake manifold after the aftercooler.

1. Disconnect line (A) from intake manifold and install the

appropriate fitting from JDE147 Manifold Pressure Test

Kit or FKM10002 Universal Pressure Test Kit.

Additional adapter fittings may be needed: M10 x 1

and M14 x 1.5.

Connect gauge (B) and hose assembly to fitting. Be

sure all connections are tight.

IMPORTANT: Engine speed and load should be

stabilized before taking a gauge

reading. Be sure that gauge works

properly and familiarize yourself with

the use of the gauge.

Turbo-boost pressure checks are only a

guide to determine if there is an engine

problem (valve leakage, faulty nozzles,

etc.). Low pressure readings are not a

conclusive reason for increasing

injection pump fuel delivery. Pump

adjustment should be within

specifications as established by an

authorized diesel repair station.

2. Before checking boost pressure, warm up engine to

allow the lubricating oil to reach operating temperature.

IMPORTANT: On some vehicles, it may not be

possible to meet the turbo boost

pressure due to inability to get full load

rated speed. In these cases, see

Machine Operation and Test Manual for

the appropriate test method and

pressure.

3. Place engine under full load at rated speed to make

test.

4. Observe pressure reading on gauge. Compare

readings with charts in Section 06, Group 210. Boost

pressure should be within ranges shown in charts

when engine is developing rated power at full load

rated speed.

5. If boost pressure is too high, remove fuel injection

pump and have it checked for high fuel delivery by an

authorized diesel repair station.

If boost pressure is too low, check the following:

· Restricted air filter elements.

· Restricted fuel filter elements.

· Incorrect fast idle adjustment.

· Incorrect injection pump timing.

· Exhaust manifold leaks.

· Intake manifold leaks.

· Faulty fuel transfer pump.

· Low compression pressure.

· Faulty fuel injection nozzles.

· Carbon build-up in turbocharger.

· Turbocharger compressor or turbine wheel rubbing

housing.

· Low fuel injection pump fuel delivery.

· Restricted exhaust.

6. After completing test, remove test equipment and fitting

and reconnect line to intake manifold. Tighten securely.

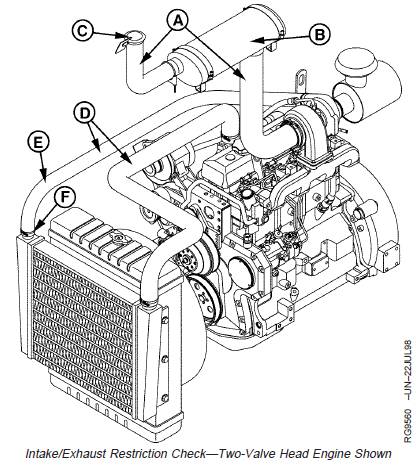

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)檢查進(jìn)氣和排氣限制

A—Exhaust Piping C—Rain Cap E—Elbow F—Connection

B—Muffler D—Intake Piping

Low power, low boost pressure, and excessive black

exhaust smoke can be caused by an intake air or

exhaust restriction.

1. Inspect the exhaust piping (A), the muffler (B), and

the rain cap (C) for damage or any possible

restrictions.

2. Inspect the intake piping (D), any elbows (E), and

any connections (F). Look for collapsed pipes,

dented pipes and loose connections. Replace

components as needed.

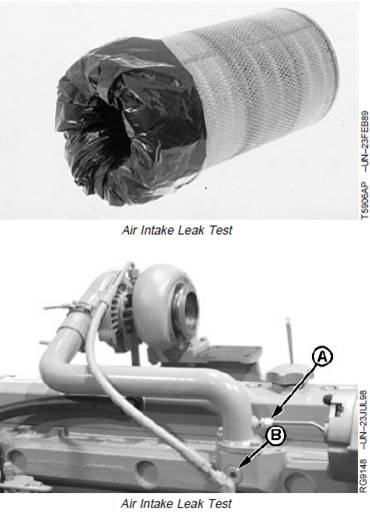

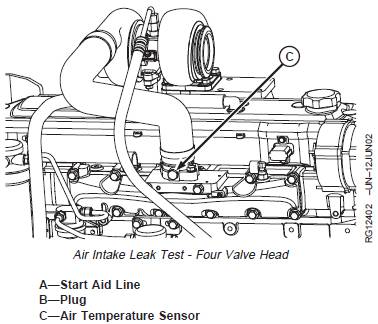

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)進(jìn)氣泄漏試驗(yàn)

Loose connections or cracks in the suction side of the air

intake pipe can allow debris to be ingested into the engine

causing rapid wear in the cylinders. Additionally, on

turbocharged engines, compressor damage may occur

and cause an imbalance resulting in bearing failure.

Air leaking from loose connections or cracks on the

pressure side of the turbocharger can cause excessive

smoke and low power.

NOTE: The following test procedure requires that the air

intake be sealed off to pressurize the system.

Using a plastic bag to seal the air intake filter is

used as an example.

CAUTION: Do not start engine during this test

procedure. Plastic bag (or whatever

material/object used to seal intake) can be

sucked into the engine.

1. Remove air cleaner cover and main filter element.

2. Put a plastic bag over secondary filter element and

install main element and cover.

3. For two valve head engines, remove plug (B) from

manifold or disconnect start aid line (A) from crossover

tube (if equipped).

4. For four valve head engines, remove air temperature

sensor (C) from manifold.

5. Using a adapter, connect a regulated air source.

6. Pressurize air intake system to 13.8—20.7 kPa

(0.13-0.21 bar) (2—3 psi).

7. Spray soap and water solution over all connections

from the air cleaner to the turbocharger or air inlet to

check for leaks. Repair all leaks.

8. Remove plastic bag from filter element and reinstall

element and cover.

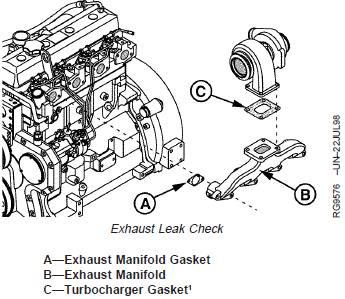

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)檢查排氣漏氣(渦輪增壓)

Exhaust leaks, upstream of the turbocharger, will cause

the turbocharger turbine to rotate at a reduced speed

resulting in low boost pressure, low power, and excessive

black smoke.

IMPORTANT: Avoid engine damage and failure. There

are two types of gaskets: single entry

and dual entry. Single entry is

completely open in the center and dual

entry has a divider in the center. Do not

interchange dual and single entry

gaskets.

Inspect the exhaust manifold gasket (A), the exhaust

manifold (B), and the turbocharger gasket (C) for damage

and any signs of leakage. Replace components as

needed.

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)OEM發(fā)動(dòng)機(jī)技術(shù)規(guī)格

General OEM Engine Specifications

Tier I Engines

ITEM ENGINE

4045DF150 4045TF150 4045TF250 4045HF150 6068DF150 6068TF150 6068TF250 6068HF150 6068HF250

Number of Cylinders 4 4 4 4 6 6 6 6 6

Bore 106 mm 106 mm 106 mm 106 mm 106 mm 106 mm 106 mm 106 mm 106 mm

(4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.) (4.19 in.)

Stroke 127 mm 127 mm 127 mm 127 mm 127 mm 127 mm 127 mm 127 mm 127 mm

(5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.) (5.0 in.)

Displacement 4.5 L 4.5 L 4.5 L 4.5 L 6.8 L 6.8 L 6.8 L 6.8 L 6.8 L

(276 cu (276 cu (276 cu (276 cu (414 cu (414 cu (414 cu (414 cu (414 cu

in.) in.) in.) in.) in.) in.) in.) in.) in.)

Compression 17.6:1 17.0:1 17.0:1 17.0:1 17.6:1 17.0:1 17.0:1 17.0:1 17.0:1

Max. Crank Pressure 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa 0.5 kPa

(2 H2O) (2 H2O) (2 H2O) (2 H2O) (2 H2O) (2 H2O) 2 H2O) (2 H2O) (2 H2O)

Governor Regulation 7—10 % 7—10 % 7—10 % 7—10 % 7—10 % 7—10 % 7—10 % 7—10 % 7—10 %

(Industrial)

Governor Regulation 5 % 5 % 5 % 5 % 5 % 5 % 5 % 5 % 5 %

(Generator)

Oil Pressure Rated 345 kPa 345 kPa 345 kPa 345 kPa 345 kPa 345 kPa 345 kPa 345 kPa 345 kPa

Speed (50 psi) (50 psi) (50 psi) (50 psi) (50 psi) (50 psi) (50 psi) (50 psi) (50 psi)

Oil Pressure Low Idle 105 kPa 105 kPa 105 kPa 105 kPa 105 kPa 105 kPa 105 kPa 105 kPa 105 kPa

(15 psi) (15 psi) (15 psi) (15 psi) (15 psi) (15 psi) (15 psi) (15 psi) (15 psi)

Length 861.0 mm 861.0 mm 861.0 mm 861.0 mm 1117 mm 1117 mm 1117 mm 1116 mm 1141 mm

(33.9 in.) (33.9 in.) (33.9 in.) (33.9 in.) (44.0 in.) (44.0 in.) (44.0 in.) (43.9 in.) (44.9 in.)

Width 598 mm 598 mm 598 mm 598 mm 598 mm 598 mm 598 mm 623 mm 623 mm

(23.5 in.) (23.5 in.) (23.5 in.) (23.5 in.) (23.5 in.) (23.5 in.) (23.5 in.) (24.5 in.) (24.5 in.)

Height 854 mm 980 mm 980 mm 980 mm 956 mm 984 mm 984 mm 1009 mm 1009 mm

(33.6 in.) (38.6 in.) (38.6 in.) (38.6 in.) (37.6 in.) (38.7 in.) (38.7 in.) (39.7 in.) (39.7 in.)

Weight 387 kg 396 kg 396 kg 396 kg 522 kg 533 kg 533 kg 550 kg 568 kg

(851 lb) (872 lb) (872 lb) (872 lb) (1149 lb) (1172 lb) (1172 lb) (1210 lb) (1250 lb)

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska