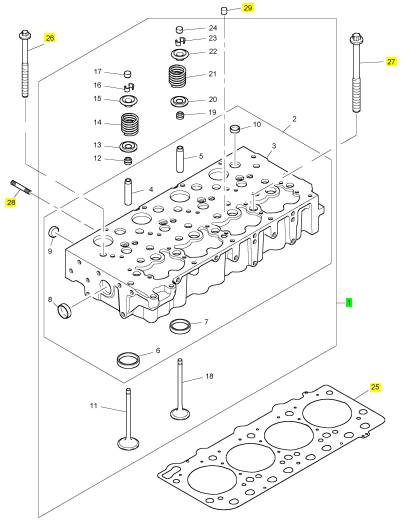

Perkins珀金斯850-854F柴油發動機T412697汽缸蓋墊片

詳細描述

項目 零配件號碼 最新件號 描述

1 1 汽缸蓋總成

25 1 汽缸蓋墊片

(25) T411894 1 T411894 汽缸蓋墊片

(25) T412697 1 T412697 汽缸蓋墊片

26 T412677 4 T412677 汽缸蓋螺拴

27 T412687 6 T412687 汽缸蓋螺拴

28 T412947 8 T412947 圖釘

29 T411791 1 T411791 合釘

|

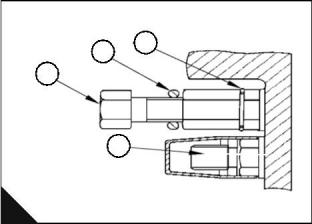

A special service version of the tamper evident body (D) must be fitted when a new fuel screw is fitted. A kit part number U5MK0619 is available from PDC. This kit will be supplied only to permitted personnel and must not be supplied to end users. A groove (D4) around the circumference of the tamper evident body is used to identify it as a service part. |

|

2 Fit the fuel adjustment screw assembly (C3) to the engine ensuring that there is a metal snap ring (C1) located in the lock nut groove and a o-ring (C2) fitted. |

|

3 On a suitable calibrated test facility, reset the engine performance parameters to the certified specification indicated on the engine's emissions control information label mounted on the timing case. |

|

4 Having set the full load fuel delivery to the certified specification and ensuring the lock nut is correctly tightened, insert the D-plug (D2) into the service tamper resistant body (D3) at the opposite end of the internal groove (D1). Fit the new service tamper resistant body assembly (D) over the fuel adjustment screw. |

|

5 Tap on the tube until the internal groove (D1) in the body engages over the metal snap ring (C1) in the lock nut. |

|

To remove and re-fit the tamper evident maximum engine speed cap |

|

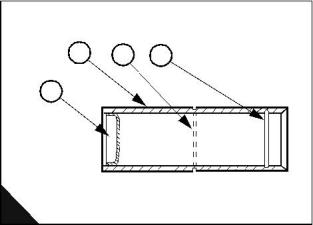

The maximum speed adjustment has a plastic cap (B4) fitted by Perkins. The length of this fitted cap will be either 22mm or 30mm in length depending on the original protrusion of the maximum speed adjustment screw (B5). The cap is pressed by hand onto the adjustment screw and an internal lip locates into a groove on the lock nut. |

|

1 Remove the plastic cap (B4) from the maximum speed bolt (B5) with a suitable lever, taking care not to damage the seal between the cylinder block and the locknut. |

|

2 Make the necessary adjustment to maximum (no load) engine speed by rotating bolt clockwise to reduce speed and anti-clockwise to increase speed with the engine throttle lever fully open. |

|

Note: The only permitted adjustment to the maximum engine speed is to correct the speed in accordance with the high idle speed shown on the emissions compliance label mounted on the engine timing case. |

|

3 After adjustment to within the certified maximum speed range, a new service cap of the appropriate length can be obtained from PDC Irlam. The replacement service cap will be red in colour part number 131276440 - 30mm length or 131276450 - 22 mm length. This cap will be supplied only to permitted personnel and must not be supplied to end users. |

|

4 Hand press the replacement service cap onto maximum speed bolt (C4) lock nut. |

|

A warranty claim will not be accepted if it can be seen that an adjustment to the maximum engine speed setting (B5) or the fuel adjustment screw (B2) has been made by personnel not approved by Perkins. |

|

1 |

|

2 |

|

3 |

|

4 |

|

1 |

|

3 |

|

2 |

|

4 |

|

c C |

|

D |

|

74 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

6 |

|

100 Series |

|

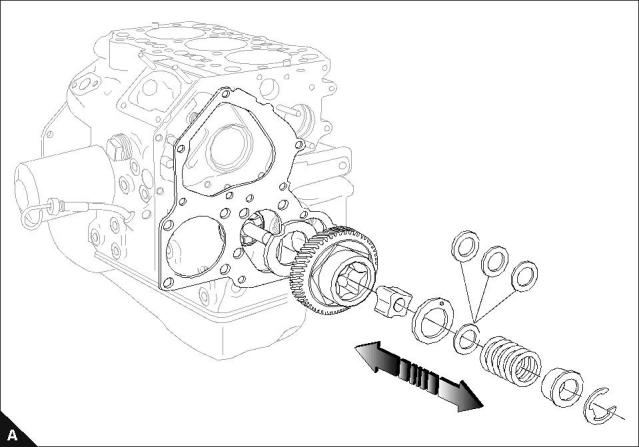

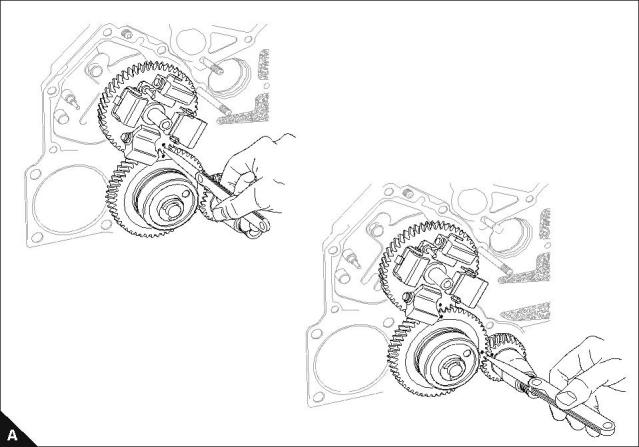

Idler gear and oil pump |

|

To remove and to fit |

|

Operation 6-10 |

|

Special requirements |

|

Clearance (B1) mm (in) |

|

Standard |

|

Service limit |

|

0,01 - 0,15 (0.0004 - 0.0060) |

|

0,25 (0.0098) max |

|

Extra shims may be required to achieve the standard clearance. To check the end float refer to Operation 6-13. |

|

1 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

75 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

6 |

|

100 Series |

|

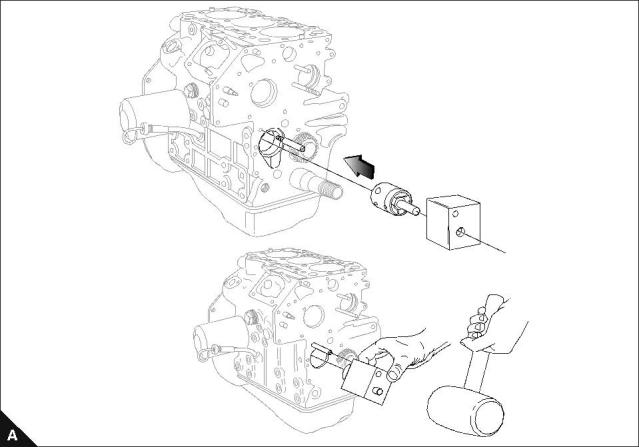

Idler hub |

|

To fit |

|

Operation 6-11 |

|

Special requirements |

|

Special tools |

|

Description |

|

Part number 21825624 |

|

Idler hub assembly tool - 102-05, 103-07 Idler hub assembly tool - 103-10 |

|

21825625 |

|

Idler hub assembly tool - 103-13, 103-15, 104-19, 104-22 |

|

21825626 |

|

Caution: If the idler hub is removed, it must be renewed. |

|

76 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

6 |

|

100 Series |

|

Gear teeth backlash |

|

To check backlash |

|

Operation 6-12 |

|

Special requirements |

|

Timing gear tolerances mm (in) |

|

Standard |

|

Service limit |

|

0,08 (0.0032) |

|

0,25 (0.0098) |

|

1 Align the set marks. |

|

2 Measure the clearance with a feeler gauge. |

|

Workshop Manual, TPD 1377E, issue 4 |

|

77 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska